SCHWEISSEN UND SCHNEIDEN

"Peer Reviewed Journal" seit 1949

Ausgewiesene Fachleute berichten Monat für Monat über Ergebnisse von Entwicklungs- und Forschungsarbeiten aus allen Bereichen der Industrie und geben ihre Erfahrungen für die Anwendung der Schweißtechnik in der Praxis weiter. Die Fachzeitschrift SCHWEISSEN UND SCHNEIDEN ist damit eine wichtige Informations- und Entscheidungsquelle für Leser aus der Forschung, der Lehre, der Wirtschaft und der Industrie.

Ausgabe 12

Ausgaben-Highlights:

Hybride Verbindungen neu gedacht

Die Fertigung hybrider Bauteile stellt Entwicklerinnen und Entwickler zunehmend vor komplexe technische und wirtschaftliche Aufgaben. Um das Bauteilgewicht zu reduzieren, müssen häufig Werkstoffkombinationen verwendet we...

Einsatz von MSG-Zweidrahtprozessen mit nicht artgleichen Drahtelektroden zur Steigerung der Korrosionsbeständigkeit von Schweißplattierungen

In diesem Beitrag werden ausgewählte Ergebnisse aus einem IGF-Forschungsvorhaben zum Schweißplattieren von Überhitzerrohren mittels Heißdraht (HD)-unterstütztem Metallschutzgas (MSG)-Schweißprozess mit verschiedenen korr...

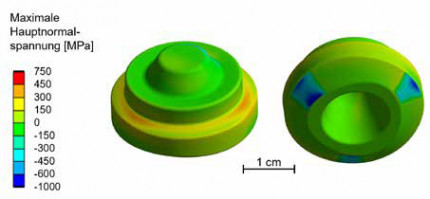

Entwicklung keramikgerechter Werkzeuge für das Rührreibschweißen von Stahlwerkstoffen

Das Rührreibschweißen von Stählen gilt aufgrund der hohen Anforderungen an Anlagen und Werkzeugwerkstoffe weiterhin als anspruchvollste Anwendung dieser Fügetechnologie. Die Wirtschaftlichkeit des Verfahrens wird jedoch...